Vecmocon Internal Tool (VIT): Building the Central Nervous System for a Scaling Hardware Company

Project Overview

Vecmocon produces complex hardware ecosystems (IoT, BMS, Chargers). As the company scaled, reliance on scattered spreadsheets and individual hard drives for tracking production became a liability. We needed a centralized source of truth.

VIT (Vecmocon Internal Tool) is a comprehensive web application acting as a bespoke ERP. It centralizes the lifecycle of every product produced, from manufacturing and testing to dispatch, repair, and SIM management.

Role

Lead Designer

Team

2 Designers , BMS Team, CXOs and Developers

Platform

Web Application

Timeline

8 Months (Ongoing)

The Challenge

Before VIT, Vecmocon operated on tribal knowledge and decentralized data. Critical information—firmware versions, testing logs, and dispatch records—lived in isolated Google Drives or local machines.

The friction:

Lack of Traceability

If a product failed in the field, tracing its manufacturing batch or test results took hours of manual digging.

High Failure Risk

Without system checks, human error could lead to dispatching devices with outdated firmware or incorrect configurations.

Operational Bottlenecks

Service teams couldn't see production data, and Sales couldn't see live inventory.

The Goal

To design a unified platform that acts as the "Golden Thread" connecting a physical product to its digital history, enabling data-driven decisions and preventing operational failures.

Discovery & Research

As the Design Lead, I established that we couldn't design this sitting at our desks. We needed to understand the physical constraints of our users.

We visited the production facility to observe how packers physically handled devices, identifying where scanning errors occurred. We traveled to field service centers to map the journey of a damaged component from "Inward" to "Repair" to "Final Test." We conducted sessions with Product Managers, Embedded Engineers, and the Quality Team to understand the specific data points required for Root Cause Analysis (RCA).

Information Architecture & Solution

VIT is massive. To make it digestible, we modularized the architecture based on the user's operational vertical, all tied together by a robust User & Role Management system to ensure security.

Product & Masterdata

Enter Product ID to reveal its entire history - manufacturing date, current location, firmware version, and service history. Masterdata allows admins to configure product codes, components, and customer lists without code changes.

Quality

View and track FCT (Functional Circuit Test) and PDI (Pre-Delivery Inspection) results in a click.

Dispatch

This module directly impacts revenue. If we ship the wrong item, we lose money. The UI blocks the user if a scanned item doesn't match the shipment manifest, reducing logistics errors to near zero.

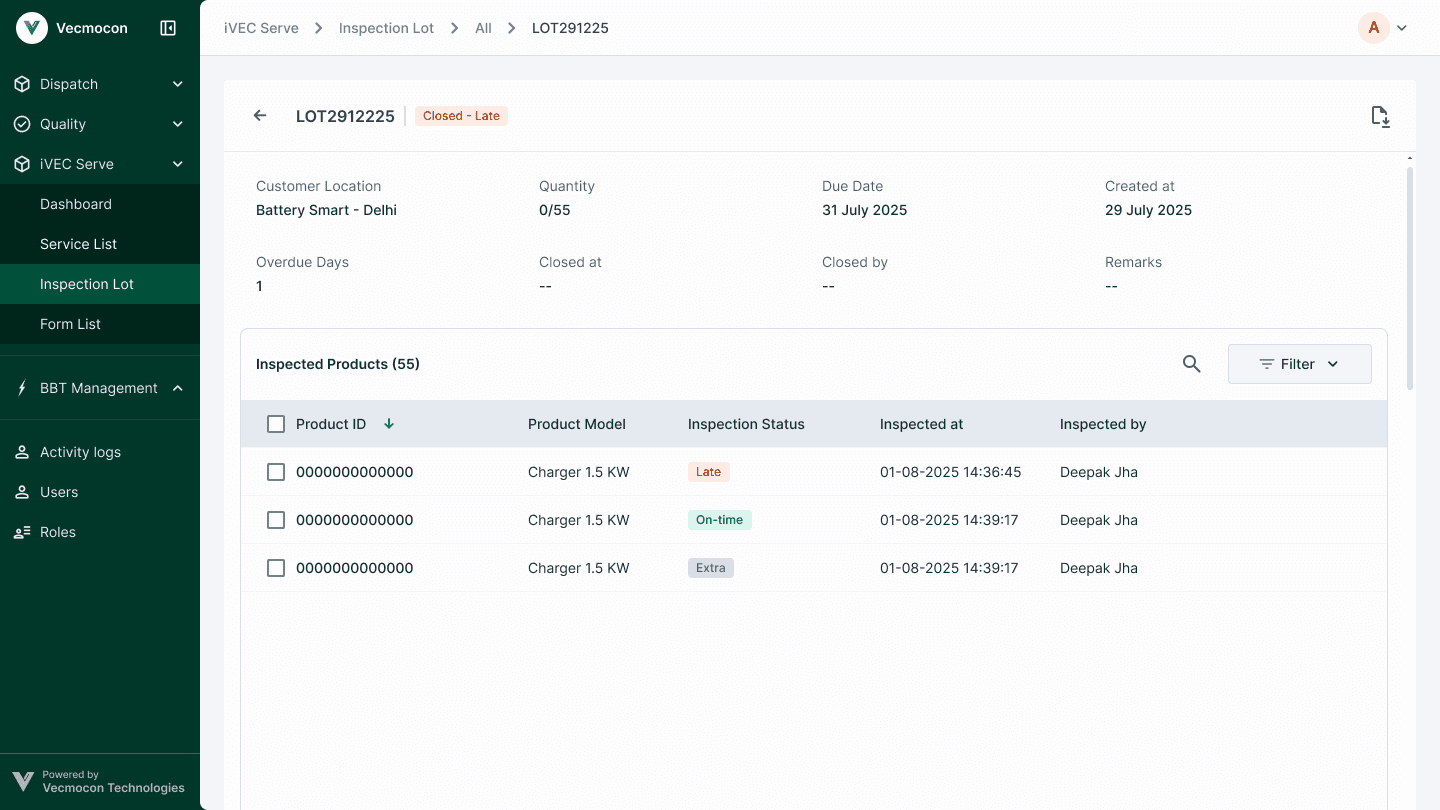

Service

This was the most complex module due to intricate Service Level Agreements (SLAs). We created a "Status Pipeline" view so Service Managers could instantly see bottlenecks (e.g., "5 items stuck in Inspection for > 2 days").

BMS Logs

A dedicated module tracks firmware changes and configuration edits, providing an audit trail of who changed what and when.

SIM Management

A financial dashboard allowing the Sales team to track IoT SIM activations, suspend non-paying customers, and automate payment reminders.

Results and Impact

VIT has transformed from a utility tool to a business intelligence asset.

Centralized Truth

Eliminated dependency on individual hard drives. Anyone with permission can now trace a product's history in seconds.

Reduced Logistics Errors

The validation checks in the Dispatch module significantly reduced wrong-product shipments.

Faster RCA